Physics of Fluids

Volume 35, Issue 11, November 2023

Laser-Induced, Single Droplet Fragmentation Dynamics Revealed Through Megahertz X-ray Microscopy

by Fabian Reuter, Tokushi Sato, Valerio Bellucci, Sarlota Birnsteinova, Carsten Deiter, Jayanath C. P. Koliyadu, Romain Letrun, Pablo Villanueva-Perez, Richard Bean, Adrian P. Mancuso, Alke Meents, Patrik Vagovic, Claus-Dieter Ohl

Featuring a pair of Shimadzu Hyper Vision HPV-X2 ultra high-speed video cameras, lasers and X-ray microscopy.

ABSTRACT

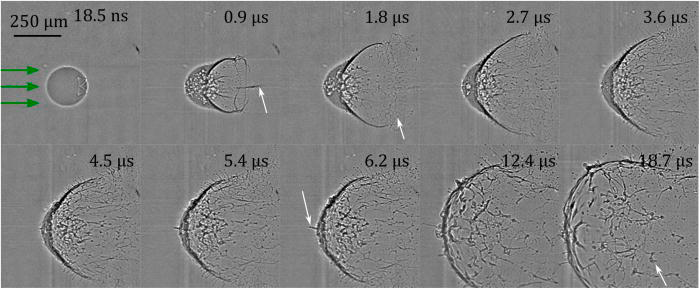

The fragmentation dynamics of single water droplets from laser irradiation is studied with megahertz frame rate X-ray microscopy. Owed to the nearly refraction-free and penetrating imaging technique, we could look into the interior of the droplet and reveal that two mechanisms are responsible for the initial explosive fragmentation of the droplet. First, reflection and diffraction of the laser beam at the droplet interface result in the formation of laser ray caustics that lead to non-homogeneous heating of the droplet, locally above the critical temperature. Second, homogeneous cavitation in the droplet that is likely caused from shockwaves reflected as tension waves at the acoustic soft boundaries of the droplet. Further atomization occurs in three stages, first a fine sub-micrometer sized mist forms on the side of the droplet posterior to laser incidence, then micrometer sized droplets are expelled from the rim of an expanding liquid sheet, and finally into droplets of larger size through hole and ligament formation in the thinning liquid sheet where ligaments pinch off.

I. INTRODUCTION

Atomization is the process of fragmenting larger liquid masses into smaller droplets and fine sprays. It may be desirable in industrial and medical applications, yet it also could be undesired in modern liquid droplet shaping. In many of the processes resulting in droplet atomization, shock waves interact either externally with the droplet or are created within. For example, the impact of rain on fast-moving planes and trains results in shock and expansion waves that once launched within the droplet may atomize the droplet by overcoming the yield strength of the liquid. In particular, expansion waves formed upon an acoustic soft reflection of shock waves may cause a vapor phase explosion within the droplet.

In addition to the droplet impact, pressure waves may be generated with pulsed lasers or X-ray illumination. When the liquid is opaque to the radiation, momentum can be transferred through the vaporization of a thin layer of liquid, thus propelling and deforming the liquid sphere into a thin and radially expanding sheet. At higher laser intensities within nontransparent droplets, shocks may be launched that result in spallation and cavitation within the droplet. In less-absorbing liquids, this phase transition may be initiated through an optical breakdown, resulting in an explosively expanding vapor bubble that also launches shock waves. The complexity of the droplet atomization is caused by the interaction of the shock waves and cavitation bubbles with the liquid–gas interface, giving rise to Rayleigh–Taylor instabilities, spallation, and secondary cavitation. A technical application is the shaping of droplets into thin sheets, which is a prerequisite for the generation of extreme UV light. This is currently done through pulsed laser illumination of liquid tin droplets. With increasing laser intensities or smaller droplet sizes, the droplet may not form a sheet but grows in volume and develops radially outward pointing jets on its surface; both features are driven by expanding cavitation bubbles within the droplet. Yet it is not clear where the phase transition occurs. Even in a surrogate liquid such as water, the small size of the droplet prevents a look into the complex fluid dynamics at very short time scales when using visible light.

The time-resolved MHz X-ray microscopy developed at European XFEL used here overcomes these limitations. In particular, the nearly refraction-free illumination offers a view into the droplet and also has a nearly infinite depth of field to resolve the three-dimensional fragmentation dynamics.

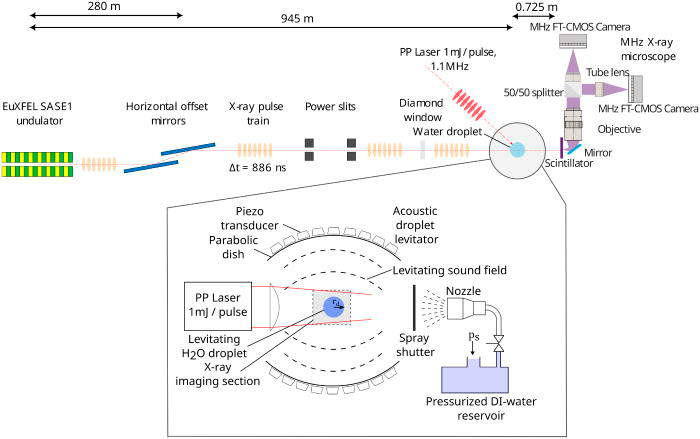

II. EXPERIMENTAL SETUP

A sketch of the droplet generation and laser-fragmentation setup is given in Figure 1. A single, sub-millimeter-sized droplet of de-ionized water was acoustically levitated in air. The beam of a pulsed laser (wavelength: 1030 nm, pulse energy attenuated to 1 mJ, pulse duration 850 fs, and spot size FWHM m; laser developed at European XFEL facility) was made slightly convergent with a lens located close to the droplet (focal length mm) and aligned to completely illuminate the droplet from one side. As the droplet was hit by the laser, a rapid phase explosion fragmented the droplet. The fragmentation dynamics was recorded with the MHz X-ray microscopy setup developed within an internal R&D project of European XFEL, based on an indirect X-ray detector, a fast scintillator, a diffraction limited optical microscope with near ultraviolet (NUV) optics, and two megahertz cameras Shimadzu HPV-X2. A magnification was obtained with a 10× objective (Mitutoyo long working distance objective, 10×, NUV, 0.28 NA) resulting in an effective pixel size of 3.2 μm. The X-ray pulse repetition rate is 1.125 MHz, and both high-speed cameras are synchronized to the X-ray pulses to record one image per X-ray pulse. Additionally, the cameras are aligned back to back in time, extending the image buffer to 256 frames at full spatial resolution instead of the 128 frames for a single camera. The schematic configuration of the experiment is sketched in Figure 1.

Figure 1. Schematics of experimental arrangement with direct beam illumination at SPB/SFX instrument at EuXFEL (top) and sample setup (bottom). A water spray is produced through a nozzle, and a water droplet (of a specific size) is trapped in the standing wave field of the acoustic levitator. A mildly convergent laser pulse explosively fragments the quiescent droplet. The time-resolved dynamics are recorded in the X-ray imaging section.

An avalanche photodiode was used to measure the instance of laser pulse impact on the droplet with respect to the first frame of the imaging series where the uncertainty is estimated to be below 1 ns, which results from the uncertainty of the distance between droplet and photodiode and the finite speed of light.

To study a symmetric and unbounded droplet, a single droplet was trapped in an in-house built acoustic levitator based on the TinyLev design. It consists of two spherical caps, each equipped with 36 piezoelectric transducers. The spherical caps are mounted at a distance of mm to form a standing wave when driven at 80 kHz. Electric driving powers were set between 5 and 15W allowing to trap droplets with a final radius between and m. These parameters allow the trapping of spherical droplets that do not show oscillations in the sound field. From the spray, a single droplet was acoustically trapped and levitated along the axis of cylindrical symmetry near the center of the levitator. The droplet generation and trapping had to be automatized, as physical access to the setup was limited during beam time. Therefore, a simple and robust remote solution of droplet generation was found by first producing a spray of fine droplets, from which then individual droplets at various pressure nodes are trapped. The spray naturally contains a broad range of combinations of droplet sizes, velocities, and injection positions with respect to the acoustic field. Thus, the necessary conditions for droplet trapping are met in some cases without the requirement for fine-tuning or readjustment of experimental parameters during the test runs. This is further discussed in Appendix A, where also a microscopic high-speed video of the spray passing through the sound field and the trapping of droplets is provided (Figure 8, Multimedia view). A short spray burst was generated from de-ionized water through a nozzle of diameter m. The de-ionized water was filled into a pressurized reservoir with a gauge pressure of connected to an air supply line. The burst duration was about 150 ms controlled with a magnetic valve. Due to the finite opening time of the valve and the elasticity of the tubing, the spray needed some time to develop, i.e., reach the desired fine droplet sizes and large velocities in the spray. Therefore, a servo-driven mechanical shutter was employed about 2 cm in front of the nozzle exit that unblocked the spray for about 30 ms only once the spray had fully formed. After a few seconds, once the droplet was quiescently trapped, the measurement started with the firing of the laser pulse and triggering of the X-ray high-speed imaging. The remote control of the repeated droplet generation was conducted with a microcontroller that controls the magnetic valve and the mechanical shutter.

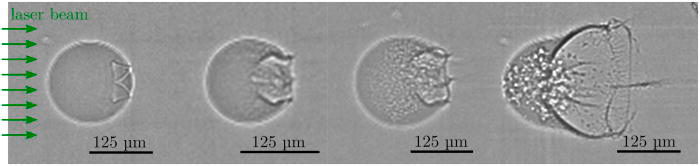

Figure 2. Initial dynamics of the exploding droplet. To achieve an increased temporal resolution, two frames from similar droplets imaged at different delays with respect to the heating laser pulse are inserted in between the first and the last frame. The time delays with respect to the laser for the four frames are 18.5, 92.5, 185, and 907 ns.

Figure 3. X-ray imaging of laser-induced fragmentation dynamics of a single water droplet levitated in the acoustic trap. The arrows in the first frame indicates the direction of the incident laser beam. Times in each frame are given with respect to the fragmenting laser pulse.

Learn more about ultra high-speed imaging solutions:

Contact a Hadland Imaging representative to learn more about ultra high-speed visible, infrared and Flash X-ray imaging solutions. Visit our page on the Shimadzu Hyper Vision HPV-X2 ultra high-speed video camera to learn more about capturing data up to 10 million frames per second for your research.

Keywords: cavitation bubbles, European XFEL, homogeneous cavitation, laser-induced single droplet fragmentation dynamics, pulsed laser illumination, Shimadzu Hyper Vision HPV-X2, shock waves, time-resolved MHz X-ray microscopy, Ultra High-Speed Imaging, X-ray illumination, X-ray microscopy