EXCLUSIVE NORTH AMERICA & EUROPE AUTHORIZED REPRESENTATIVE OF THE SHIMADZU HYPER VISION LINE OF ULTRA HIGH-SPEED VIDEO CAMERAS

High-Speed & Ultra High-Speed DIC (digital image correlation) Solutions

Pair the best high-speed & ultra high-speed video cameras with the incredible Shimadzu Material Testing Machines for the ultimate 2D/3D DIC imaging solution.

High-Speed & Ultra High-Speed DIC

We’ve got your DIC needs covered with a single camera for 2D DIC and a two camera setup for 3D DIC. Pair your choice with an incredible material testing machine, light it up with the brightest, high-intensity LED lighting system and start acquiring data. Process your data with the latest in testing & motion analysis software from Shimadzu, REL, Correlated Solutions and Xcitex to get the job done right.

Ultra High-Speed 2D/3D DIC Can’t Be Wrong

Download our DIC Solutions brochure PDF

A Good Practices Guide for Digital Image Correlation

International Digital Image Correlation Society, Jones, E.M.C. and Iadicola, M.A. (Eds.) 2018

![]()

A Good Practices Guide for Digital Image Correlation

The Good Practices Guide (GPG) by iDICs (International Digital Image Correlation Society) focuses on good practices for DIC measurement setup, image correlation, and basic post-processing of DIC data for strain computations. The scope of the current edition of the GPG is limited to common laboratory test conditions (which are outlined in the GPG).

This guide is designed to be both a primer training document geared towards new practitioners of DIC (supplementing vendor-based or other formal training and hardware and software-specific documentation) as well as a reference for experienced users, to refresh their fundamentals knowledge and skill sets and assist them in troubleshooting DIC measurements.

High-Speed & Ultra High-Speed Cameras

Hyper Vision HPV-X2 x2 for 3D DIC

Ultra High-Speed Video Cameras

Shimadzu Hyper Vision HPV-X2

Extremely Exquisite.

up to 10 million frames per second

Experience the Invisible with ultra high-speed video recording up to 10 million fps with 6x higher sensitivity (ISO 16000) than conventional video cameras. Featuring the FTCMOS2 Advanced Next-Generation Burst Image Sensor with a two camera synchronized recording function for 3D DIC.

The best in its class.

iX Cameras i-SPEED® 2, 5, & 7 Series

Bullet Stopping Speed.

up to 2.45 million frames per second

When the job calls for compact, mid-range or the best in ultra high-speed & high resolution, iX Cameras i-SPEED video cameras deliver exceptional performance for 2D/3D DIC in a variety of environments. Available options include optional battery packs, increased memory capacity and expandable & removable SSD storage for all of your imaging needs.

i-SPEED 203

2.76GP/s throughput

2,500 fps @ 1280 x 864 pixels

225,000 fps max frame rate

THE NEXT GENERATION

i-SPEED 509 / 511 / 514

up to 10.5GP/s throughput

up to 6,382 fps @ 1920 x 1080 pixels

up to 1 million fps max frame rate

THE NEXT GENERATION

i-SPEED 717 / 721 / 727

up to 27.1GP/s throughput

up to 8,512 fps @ 2048 x 1536 pixels

2.45 million fps max frame rate

Material Testing Machines

HITS-X Series

High-Speed Impact Testing Machines

20 m/sec max test speed & max force up to 10 kN

HITS-TX

The HITS-TX is perfect for obtaining baseline high-speed deformation behavioral data for materials by tensile testing at selectable speeds. Incorporating a new, high response detector and vibration resistant volumetric displacement meter, the HITS-TX allows highly accurate data acquisition with minimal vibration noise.

HITS-PX

The HITS-PX is the best choice for puncture testing materials using selectable impact speeds. Easily acquire various data such as test force vs displacement curves, maximum test force values, energy, and displacement of testing materials.

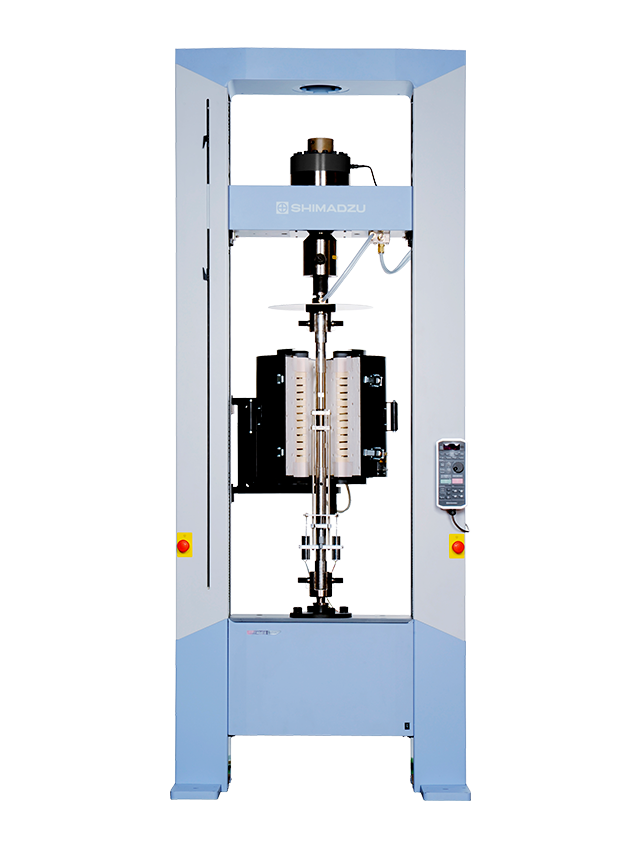

Autograph AGX-V Series

The Highest Class of Precision Universal Testing Machines

Shimadzu has been manufacturing testing machines for more than 100 years. The AGX series is the culmination of the continuous evolution of the AUTOGRAPH based on our wealth of experience and achievements, and insights from customers around the world.

At Shimadzu, our aim is to develop instruments that provide the highest level of test results. To this end, we created the AGX, the highest class of testing machine in the industry.

The AGX-V Series features:

- high rigidity frame

- multi processors

- high-speed sampling & high-accuracy automatic control

- an intelligent crosshead

- stroke limit switches

- high degree of safety for user & machine

- smart controller equipped with a progressive user interface

- software that supports the creation of test conditions & data processing with intuitive operability

Desktop and floor models available.

AGX-V 100 kN

Autograph AG-X, AGS-X & EZ-X Series

Precision Universal Testing Machines

AG-X 50 kN

AGS-X 300 kN

EZ-XS

The Shimadzu Autograph AG-X, AGS-X & EZ-X series universal testing machines deliver high-level control, intuitive operation and convenient support functions. Several standard floor and tabletop models are available with frame capacities ranging from 500 N to 2000 kN, plus options for extended frame height, wide frame & high-speed configurations. Pair one or two high-speed or ultra high-speed cameras with these incredible material testing machines for the ultimate 2D/3D DIC imaging solution.

New! Materials Testing Software

New from Shimadzu – TRAPEZIUMX-V software ensures that anyone can easily use the AGX-V, which is equipped with multiple cutting-edge functions. TRAPEZIUMX-V features a flexible UI to accommodate a variety of testing situations and is suitable for all users.

Cutting-Edge Software for Testing Machines

Shimadzu’s TRAPEZIUM X testing operation software is powerful and sets a new standard for productivity. Effortlessly enter ASTM, ISO, and JIS standard methods (tensile, compression, cycle, & texture profile examples included). One-click selection of a wide range of pre-programmed parameters & data reanalysis make data processing simple.

3D DIC (Digital Image Correlation) Using Two Shimadzu Hyper Vision HPV-X2 Cameras

Accurate synchronized recording can be performed using two HPV-X2 ultra high-speed video cameras at frame rates up to 10 million frames per second for invaluable visualization results for analysis.

3D Image Analysis Capability

Synchronize and operate multiple HPV-X2 cameras simultaneously for calibration and control using Correlated Solutions VIC-Snap Remote app for mobile devices and the VIC-3D™ System.

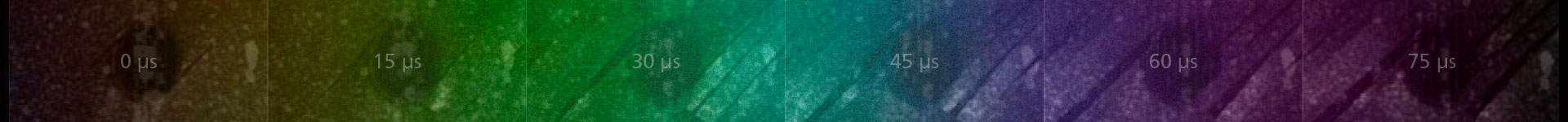

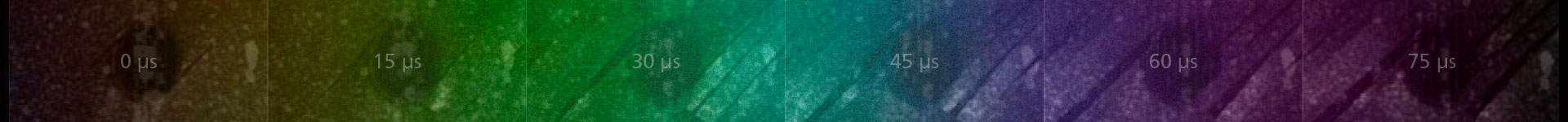

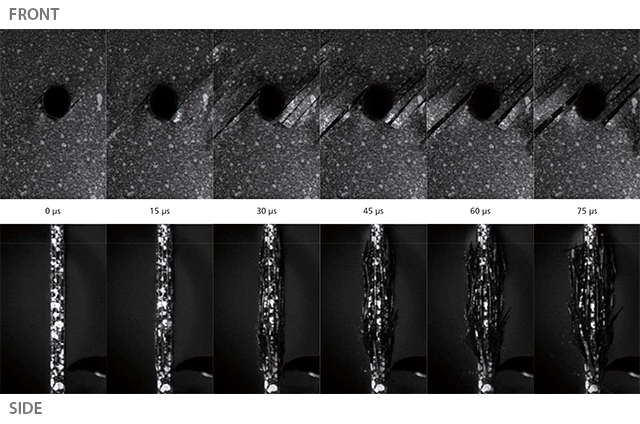

Synchronized Recording of Carbon Fiber Reinforced Plastic (CFRP) Breakage Tensile Test

The Setup

Two Shimadzu HPV-X2 ultra high-speed video cameras positioned for DIC in front of a Shimadzu AG-Xplus series precision universal testing machine.

The Results

Front & side view image results from the CFRP breakage test. Synchronized recording speed at 1 million frames per second.

Customizable High Strain Rate Testing Equipment

REL has launched SURE-Test Systems Modules for researchers to build up their high strain rate material testing capabilities. REL’s flexible SURE-Test platform offers turnkey solutions needed for tension and compression Split Hopkinson Pressure Bar (SHPB) testing, impact tests, acceleration testing, and other controlled high-energy events. Add one or two high-speed or ultra high-speed video cameras for digital image correlation to complete the system. REL’s SURE-Pulse™ Image Correlation software seamlessly packages all the data acquired during the tests into a powerful tool for efficient data processing and reporting.

REL High Strain Rate Testing Equipment 2024 Brochure

Download the REL High Strain Rate Testing Equipment 2024 brochure

– PDF format, 90 pages.

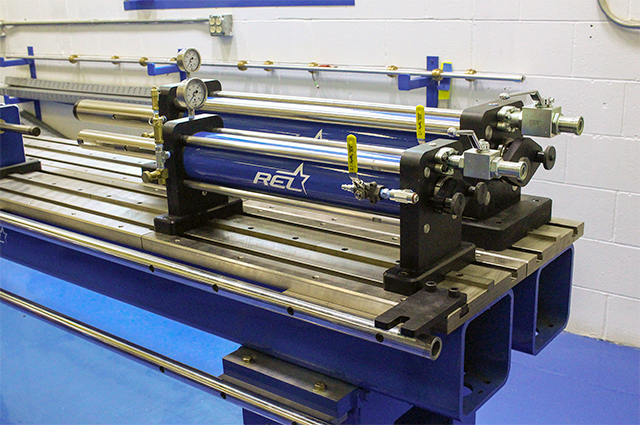

Split Hopkinson Pressure Bar/Kolsky Bar System

SURE-Test Systems from REL are designed, built, and shipped to customers worldwide.

The high strain rate testing systems can be custom built to meet your unique needs.

The 3rd Generation REL Split Hopkinson Pressure Bar/SURE-Test System has better structural performance, improved usability and safety features than previous generations. SURE-Test Systems are modular and capable of integrating different testing modules for a wide variety of configurations to meet your specific needs.

Modifications to the setup of the SURE-Test System are easily accomplished while maintaining the precise alignment that is necessary for repeatable high strain rate testing. The system features a linear rail system to mount accessory modules such as data acquisition and high-speed imaging equipment.

Contact us for more information about developing custom Split Hopkinson Pressure Bars to meet your high strain rate testing needs.

What is a Split Hopkinson Pressure Bar (SHPB)?

A Split Hopkinson Pressure Bar (SHPB) is used to test the high strain rate material properties of materials. The Hopkinson bar is used to impose a dynamic load on a material specimen akin to that which the material will experience in dynamic situations like vehicle crashes or other high-energy events.

The Split Hopkinson Pressure Bar/Kolsky Bar system includes a gas launcher, an incident bar, a transmission bar and a stopping mechanism – all aligned and mounted on a flat base.

The gas launcher is charged with pressurized gas to accelerate a striker bar at a measured velocity to create an impact incident. Striker bars of various lengths are used to produce a range of loading durations, i.e., short striker bars impart short time duration loads. The impact of the striker bar on the incident bar sends a stress pulse traveling down the incident bar at the speed of sound and is detected by a strain gage mounted on the bar.

REL SURE-Launch™ Automated Gas Guns

Automated Gas Launchers for Consistent Shot Control

SURE-Launch is a series of premium gas launchers used to consistently accelerate striker bars to precise velocities for dynamic test events. These launchers are modular in design and can precisely accelerate a range of striker sizes for tension and compression testing. Currently there are three launcher size ranges to impact bars up to three inches in diameter.

Launchers are fully automated for charging and firing with precise pressure regulation. Test velocities can be controlled and repeated to within 1% accuracy. Launchers can be packaged with custom bar sets, tension grips and momentum traps to tailor load pulses for a wide variety of materials and test configurations.

KEY FEATURES

- Standard 1, 2 and 3 inches maximum striker diameter (larger diameters available for custom order)

- Compressed gas powered (nitrogen, helium and air to 300 psi)

- Custom barrel lengths available for high speeds

- Modular for use in tension and compression testing

- Fully automated option for charge and fire control with digital pressure and velocity feedback

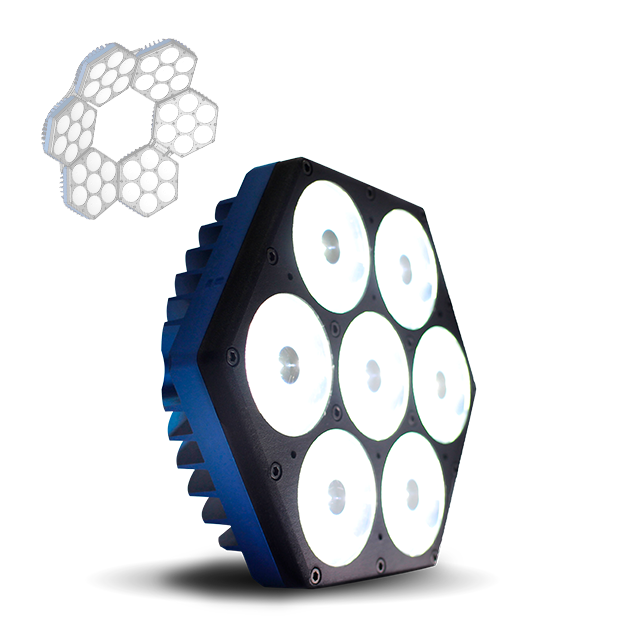

REL SURE-Bright™ LED Lighting Systems

Fixed Focused & Modular LED Lighting for High-Speed Imaging

REL SURE-Bright™ Fixed Focus Lighting System

SURE-Bright™ Fixed Focus is a tailored lighting system designed for direct sample lighting during high strain rate testing. The very high intensity focused LED light source is configured for high-speed imaging up to 5 million frames per second at a continuous duty cycle. No flash duration or delay calculations are needed. The output is dimmable from 0–100% to accommodate any exposure, sample reflectivity or lens configurations.

The light system is designed to focus a high power LED array through specialty TIR lenses onto a fixed focal point while the mounting frame allows coaxial alignment with any camera system and quick adjustments for tilting and panning. Fine lead screw adjustments are also integrated for individual camera and lighting focal distance. The high intensity continuous light source combined with the ease of adjustment and focusing ensures quick setups and consistent image acquisition. SURE-Bright™ is compatible with multi-camera setups.

KEY FEATURES

- High intensity fixed focal point light source (10Mlux peak intensity)

- 100% duty cycle at maximum output

- Low IR with minimal sample heating

- Illumination for up to 5 million frames per second in many configurations

- Variable output level (0–100%)

- Shadow-free image with concentric lens design

- Quick adjust rail mount system for reliable tilt, pan and focus setup

REL SURE-Bright™ Modular Lighting System

RELʼs SURE-Bright Modules are an expandable lighting system designed for tailorable lighting in dynamic events. Multiple modules can be linked together to achieve a focused high intensity light configured for high-speed imaging up to 5 million frames per second at a continuous duty cycle. This flexibility enables effective light to achieve high quality digital image correlation (DIC) with one camera (2D DIC) or multiple cameras (3D DIC). The output is dimmable from 0–100% to accommodate any exposure, sample reflectivity or lens configurations. The SURE-Bright Modules include Input/output triggers which can be used to connect and coordinate your testing event.

The elegantly designed light modules are engineered with 7-high power LED emitters emanating light through specialty catadioptric lenses. The lenses mounting plate allows for focusing of the light at adjustable distances (3–20 feet). Modules can be mounted on free standing tripods or paired with any camera system mounting. The high intensity continuous light source combined with the ease of expandability and focusing ensures quick setups and consistent image acquisition. SURE-Bright Modules are compatible with multi-camera setups.

KEY FEATURES

- High intensity fixed focal point light source (10Mlux peak intensity)

- 100% duty cycle at maximum output

- Low IR with minimal sample heating

- Illumination for up to 5 million frames per second in many configurations

- Variable output level (0–100%)

- Up to 8 modules linked together on a single power supply

- Built-in Laser Focus to insure peek intensity on critical focus locations

What are you waiting for?

Press the button already or call 1-888-43HADLAND (1-888-434-2352) to get your ultimate 2D/3D DIC imaging solution (or at least find out more information).