ScienceDirect

Featured in Composites Science and Technology

Volume 203, 8 February 2021, 108607

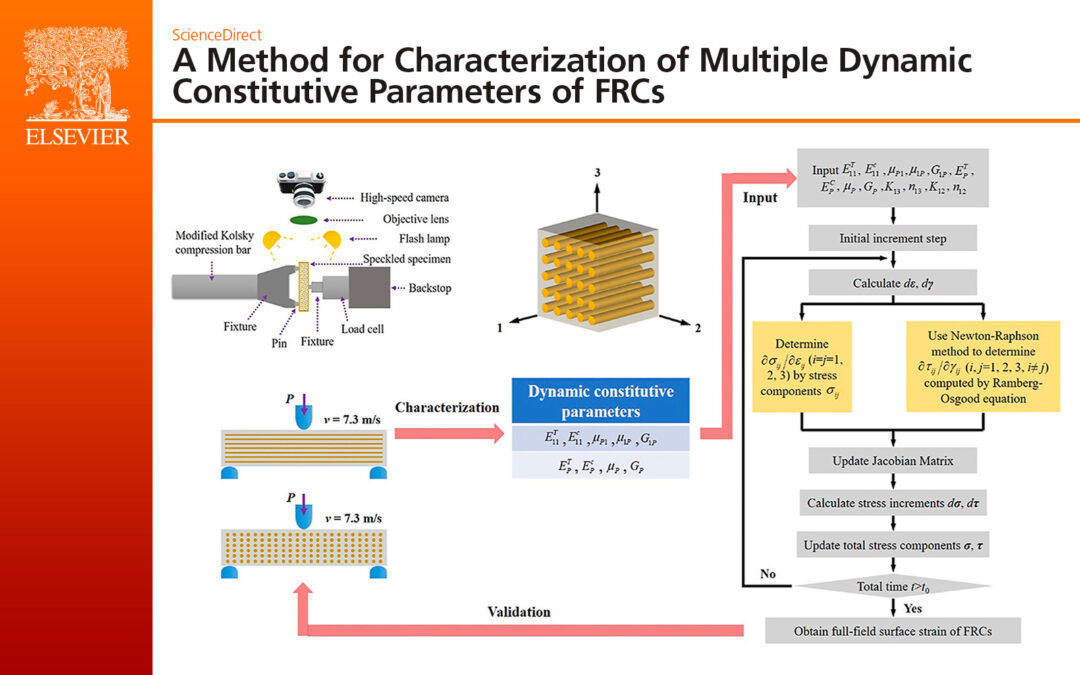

A Method for Characterization of Multiple Dynamic Constitutive Parameters of FRCs

by Jinling Gao, Cody D.Kirk, Nesredin Kedir, Shane Paulson, Julio Hernandez, Jian Gao, Xuedong Zhai, Junyu Wang, Todd Horn, Garam Kim, Francesco De Carlo, Pavel Shevchenko, Tyler N. Tallman, Giuseppe R. Palmese, Ronald Sterkenburg, Weinong Chen

Abstract

We propose a method to measure multiple dynamic material constitutive parameters of unidirectional fiber reinforced composites (FRCs) in a single experiment. Dynamic short-beam shear (DSBS) experiments were performed on a modified Kolsky compression bar, with integration of high-speed imaging and digital image correlation (DIC). The unidirectional FRCs investigated were S-2 glass fiber reinforced matrix of TGDDM-Jeffamine® D230 with monoamine functionalized partially reacted substructures (mPRS) and commercially available SC-15. Analytical solutions of normal and shear strains of a composite beam were derived based on Timoshenko beam theory, assuming material to be transversely isotropic and have different moduli in tension and compression in each principle material orientation. Tensile and compressive moduli were inversely computed through monitoring normal strain slope when specimen was constantly loaded at a speed of ~7.3 m/s within a small deflection. Non-linear shear stress-strain behavior of the composite was described via Ramberg–Osgood equation. Finite element (FE) analysis was conducted in ABAQUS, simultaneously defining via user subroutine UMAT the transverse isotropy of material, bi-modulus constitutive model, and non-linear shear stress-strain relation. The method proposed in this work was validated by comparing strain distributions computed by FE model and DIC measurements. Comparing with traditional dynamic tensile, compressive, and shear experiments on FRCs, this method significantly simplifies the specimen preparation and design of complicated gripping fixtures for multiple experiments. Furthermore, systematic errors resulting from variations of specimen geometry and dimension, loading direction, and instrumentation are reduced, thereby providing compatible data for numerical studies on impact behavior of composites.

Learn more about 3D-DIC solutions & high-speed imaging:

Contact a Hadland Imaging representative to learn more and visit our page on DIC Solutions (digital image correlation) for more information about testing machines, high-speed cameras & everything you need to get the job done right.

Keywords: Shimadzu Hyper Vision HPV-X2, 3D-DIC, High-speed imaging, Fiber reinforced composites, Mechanical properties, High loading rate, Dynamic short-beam shear experiments, digital image correlation (DIC)